Innovations & Technology

Innovation is at the heart of our DNA. From the beginning Finalmouse has pioneered technologies that have permanently changed the industry time and time again. If you own a modern gaming mouse then chances are it has been influenced by a Finalmouse innovation.

The pursuit of lightness as a performance benchmark is core to the Finalmouse ethos. Even before our patented honeycomb chassis we had already embarked on the pursuit of lightness as early as 2015. We were the first to implement lightweight engineering into mechanical designs even before the term lightweight was associated with a gaming mouse. In fact, back then it was common place for gaming mice to come with added weights to provide a false sense of quality. Fast forward to today and there isn’t a single legitimate gaming mouse that hasn’t followed our path. It has become objectively clear that every gram is critical to performance and physical latency. Every gram reduced allows gamers to further reach pure mind-to-muscle symbiosis with their aim.

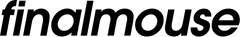

Finalmouse redefined the peripheral industry when we first introduced the patented Honeycomb lightweight chassis in 2017. The first of its kind, the Finalmouse Ultralight Pro utilized lightweight honeycomb geometry through the majority of the structural surface area. Our engineers had to analyze and develop every aspect of the mechanical design from scratch, taking into account variables like strength, thickness, and moldability just to name a few. While many imitators quickly followed none truly understood the underlying mechanical engineering principles, which is why to this day Finalmouse is the only company that implements honeycombs optimally with true lightweight engineering purpose.

After years of significant R&D into materials research, mechanical engineering, and manufacturing processes, Finalmouse released the Starlight-12 magnesium chassis in 2020. The starlight was a massive feat of engineering with each chassis needing to go through multiple fabrication processes including diecasting, CNC, stamping, polish, and chemical treatment just to name a few. Not only was the Starlight the first magnesium mouse in the world, but it also single-handedly laid the foundation and infrastructure for exotic materials to be used by the rest of the industry.

Driven by the pursuit of lightness Finalmouse continued to push forward its engineering capabilities and made further advancements in materials and mechanical science with the introduction of Carbon Fiber composite for the UltralightX. Needing to be mechanically engineered and designed from the ground up the UltralightX chassis was a massive R&D undertaking even compared to the previous generation magnesium Starlight. Finalmouse had to solve difficult problems and find novel solutions to make the manufacturability of Carbon Fiber possible at such thin nominal wall thicknesses. The innovations and cutting-edge manufacturing methods used in the ULX chassis are at the forefront of lightweight engineering for any industry; including formula one and aerospace. Being able to reduce the brittleness of Carbon Fiber, mold thin parts in volume, utilize advanced induction heat tooling, and combat RF reflectivity… are just a few of the challenges solved to ultimately make the ULX the lightest mouse in the world.

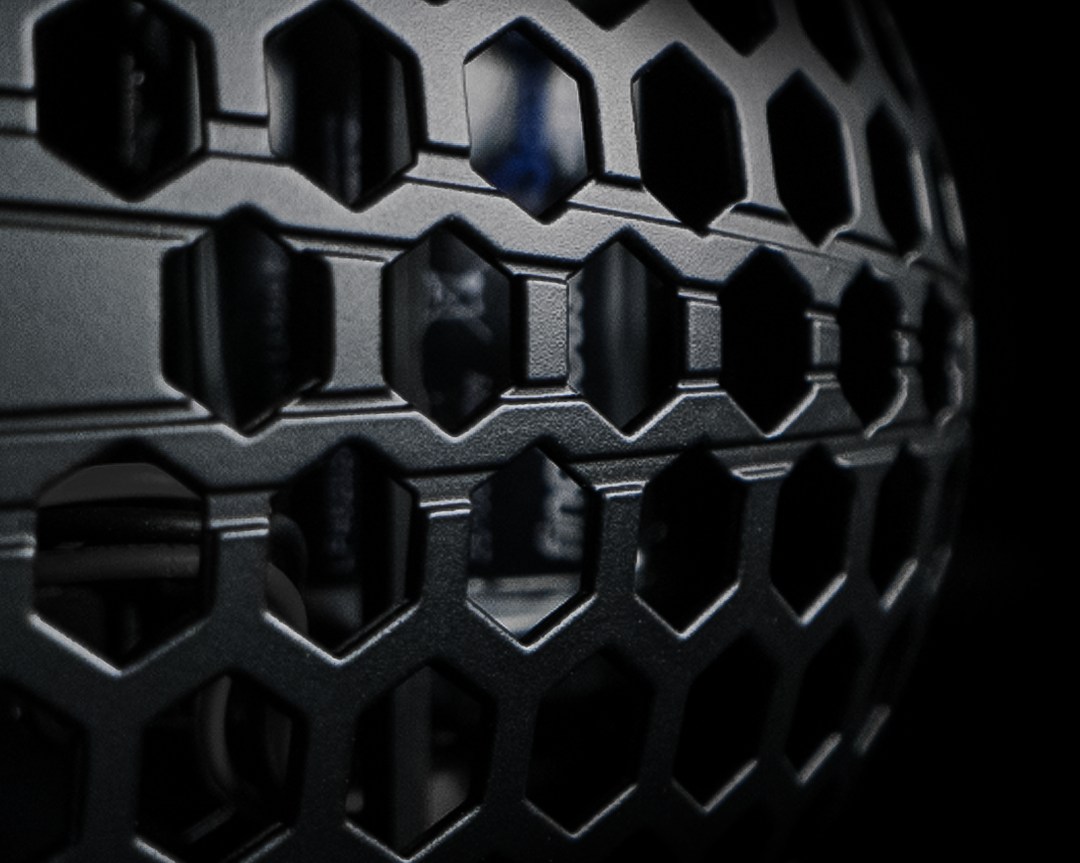

With the release of the ULX we reengineered our wireless firmware with state-of-the-art embedded systems design and cutting edge technology to push the performance benchmark to levels never before thought possible. An innovative subtick latency architecture combined with meticulous firmware optimizations has led to performance numbers that have been third party validated to be the best in the industry. For the first time we have introduced latency performance that is better than even the fastest wired mice at all polling rates. Knowing you have the fastest mouse in the palm of your hands provides a revolutionary sense of confidence for casuals up to the most elite professional players.

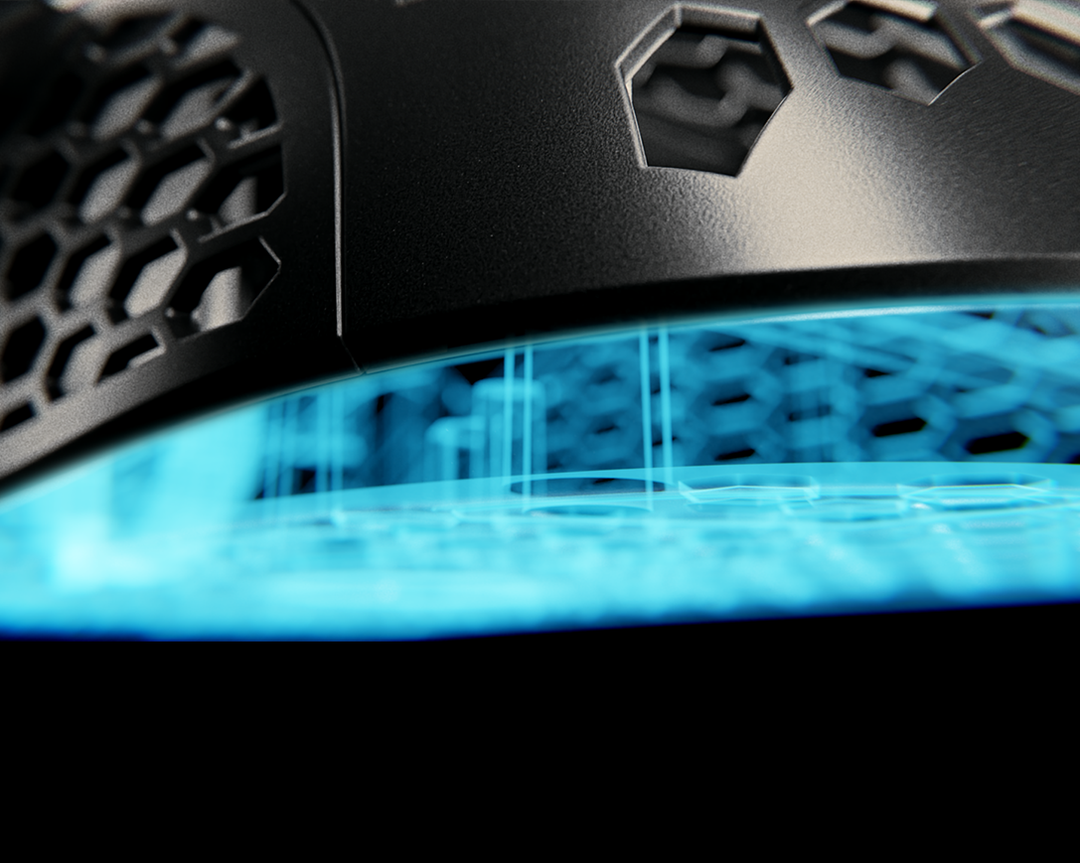

Our patented and proprietary RF escape design allows for wireless signals to escape out of the bottom shell of the mouse when utilizing exotic materials such as Carbon Fiber and Magnesium. To date our Patent protected design is the only known way to prevent a faraday cage from forming when engineering with RF reflective materials. With now many competitor mice entering the market with RF reflective materials such as magnesium they have all had to utilize Finalmouse's patented design principles. Whether legally or not...

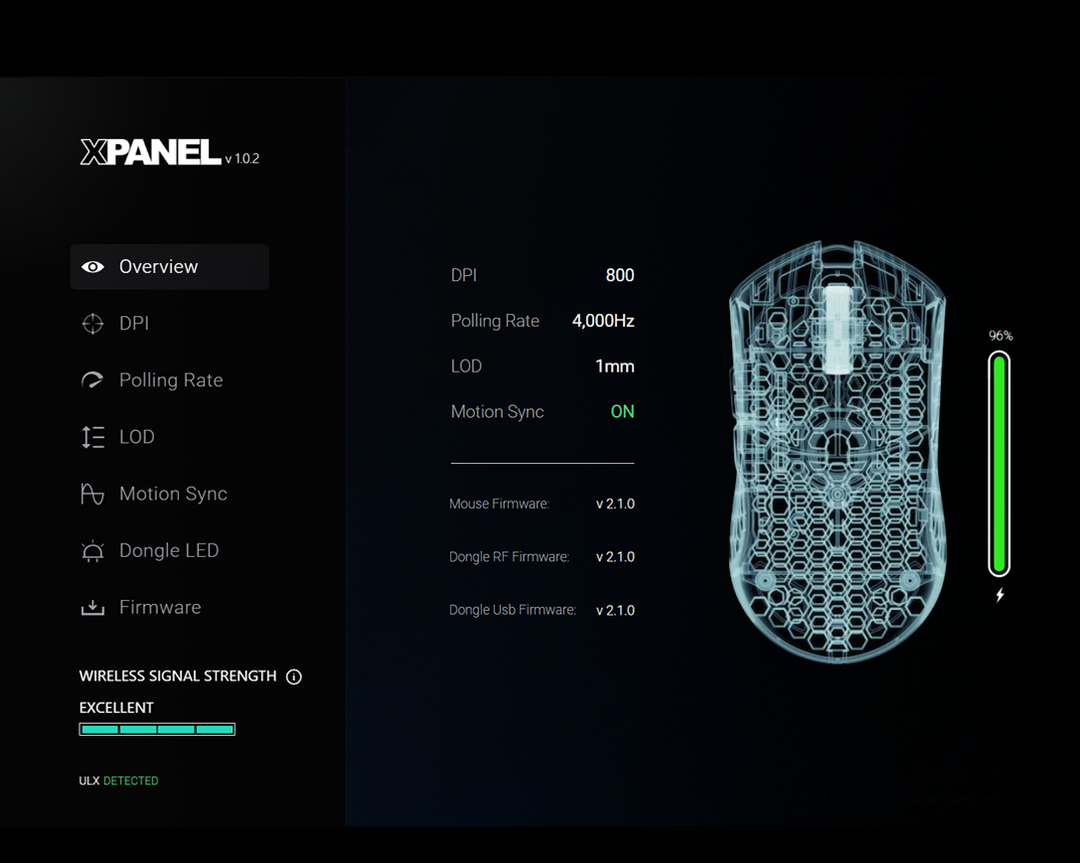

In 2023 Finalmouse became the first to develop a lightweight driverless web application for configuring a gaming mouse. Introduced with the UltralightX, xpanel is a modern web application that is driverless, bloatfree, and extremely intuitive to use. XPANEL gives users unparalleled freedom to configure, tune, and monitor their UltralightX. Our engineers developed this web app using cutting-edge browser technology to communicate over USB, directly from the browser. The only requirement in order to use XPANEL is a recent version of a Chromium-based desktop browser, such as Chrome, Edge or Opera.

In an industry filled with unoptimized OEM firmware solutions that are often shared by many brands at once, Finalmouse is the first and only company optimizing its inhouse firmware to take full advantage of the cutting edge MCU capabilities in Nordic radios and implementing advanced power consumption architectures around the chips capabilities. Our state-of-the-art firmware together with a sophisticated PCB design allows our wireless mice to have the best battery life in the industry.

With the release of the Ultralight 2 – Capetown Finalmouse introduced the world’s very first stock mouse grips called “InfinitySkins”, factory made to the dimensions of the UL2. InfinitySkins were the industry’s first mouse specific grips made by a peripheral manufacturer and paved the way for mouse grips to become the status quo in the industry. The synthetic PU leather material of InfinitySkins provided natural grip and came in various thicknesses to allow gamers to customize the dimensional feel of the mouse. As the successor to InfinitySkins we later introduced XGRIP with the release of UltralightX. This silicone-based grip is able to be manufactured in extremely thin thicknesses of .2-.3mm and provide almost no weight penalty, which is crucial in a mouse as light as the ULX.

In 2023 Finalmouse released XLAT, the worlds very first purpose built Mouse Latency Measurement Tool engineered to accurately measure the latency of wired and wireless mice. The inception of the XLAT stemmed from a need to address the shortcomings of existing latency measurement methodologies. It's repeatable, affordable, easy to use, and can be independently verified for accuracy since it's open source. This level of reliability and transparency positioned XLAT as an invaluable tool for those seeking precise and trustworthy measurements, and today you can see many brands, reviewers, and manufacturers utilizing XLAT to test their own mice.

Finalmouse was the first company to introduce flexible braided cables stock from the factory. As we continued to push mice into lighter and lighter weights it was apparent that previously stiff and heavy cables were increasingly more noticeable as a hindrance to pure aim. By experimenting with different cable layering and shielding techniques we were able to introduce what was previously only achieved through custom paracord cables in the modding community.